Process: Routing

The production process follows a logical “U” flow.

Process: Bare Wire

In the bare wire department the copper, supplied as a round cast wire, is drawn to a wire that has the

required diameter. Then one of the two rolling mills rolls the wire accurately to the desired thickness

and width.

Process: Insulation

The insulation department produces single or multi paper covered wire and glass-fibre wound wire.

Process: Enamelling

In the enamelling department the rectangular wire is, after being annealed and cleaned, coated with enamel on one of the enamelling lines.

This is done in a number of passes where, firstly, the correct amount of enamel is applied with flexible dies, secondly, the solvent in the enamel is evaporated and finally the enamel is cured. PEI/PAI enamel, called ‘SLT’, is applied for higher temperature resistant enamelled wire (temperature class 200). PVA enamel, called ‘SLN’, with the option of an epoxy layer as a bond coat, is used for oil resistant enamelled wire for CTC (temperature class E).

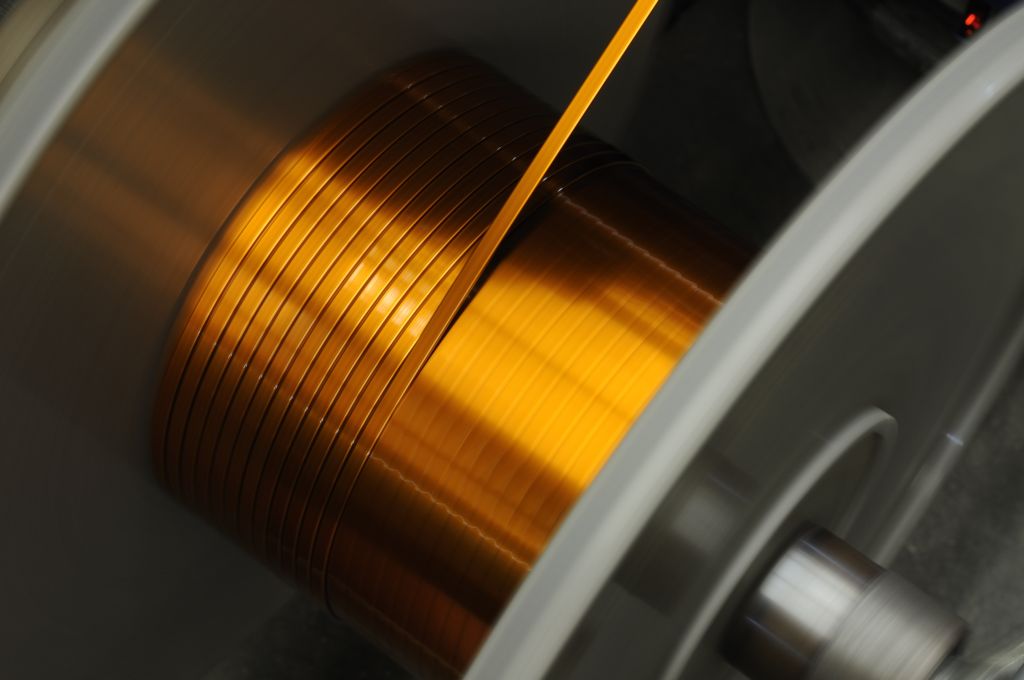

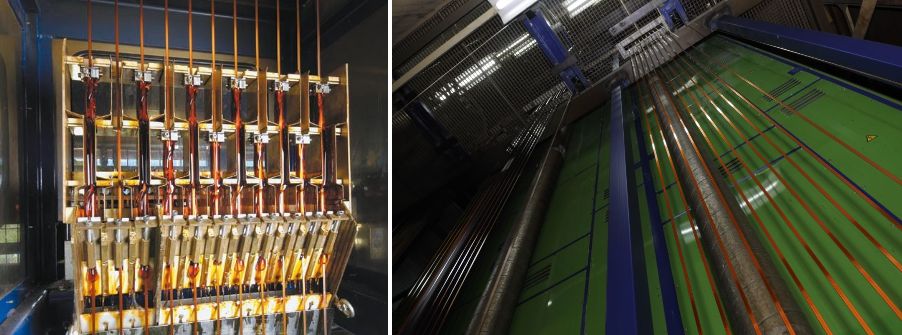

Process: CTC Production

The CTC department currently has four transposing lines. The enamelled wires are placed in cradles and guided to the transposing head. After transposition, the CTC is wrapped with insulation paper and the product is wound on a reel.

Process: Shipping

Here the final product is weighed, packed and shipped.